Manufacturing Process: Stamping and Bending

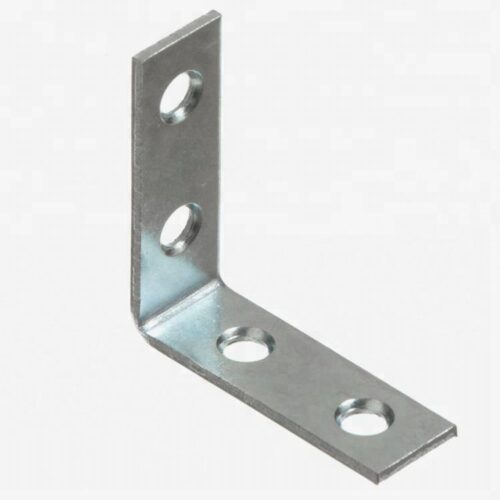

Our U brackets are manufactured using advanced metal stamping and bending processes to ensure precision and efficiency. Here’s how we produce them:

- Material Selection : We use high-quality metals such as stainless steel, aluminum, or galvanized steel based on your application requirements.

- Stamping : Flat metal sheets are cut and shaped into the desired U shape using progressive dies.

- Bending : The stamped metal is bent to form the U shape with precise angles and dimensions.

- Finishing : Surface treatments such as powder coating, anodizing, or plating are applied to enhance durability and aesthetics.

This process ensures that our U brackets are not only strong and durable but also cost-effective and customizable.

Reviews

There are no reviews yet.